Brief Introduction

The

automatic sticking machine cuts and glues the plywood to a certain depth through

a preset tool, and then conforms to the wooden strip sent by the servo, in last

to form a woodworking product.

Process Requirement

Based on the control

of the strip device technology, six new stepper motor controls are added to

achieve the tool distance setting function, which can be quickly move to a

preset distance to achieve precise control.

Solution Analysis

The

control system adopts the HMI LEVI2070D, and the PLC LX3V-1616MR2H and two

LX3V-4PG expansion modules.

Reasons for selection: Woodworking machinery

mostly uses relay type PLC as the main control, and directly controls

peripherals such as solenoid valves or inverters. At the same time, the customer

requires compatibility with the previous control scheme, and the tool can be

changed to mechanical manual tool setting.

Therefore, in the selection, the number of

relay points of LX3V-1616MR2H meets the requirements. In the aspect of 6 tool

control, the LX3V-4PG expansion module can be used uniformly to meet the

requirements. Based on the above factors, the selection configuration was

carried out.

Main control principle: The original servo control still uses

the output point on the PLC for control. The original program does not change.

The new program only increases the control of the LX3V-4PG to 6 stepping

motors.

To realize the fixed-length operation control of the stepping motor

in the program, it is necessary to have all functions such as finding the

origin, manually jogging, manual shifting, and automatic running. Provide

debuggers with as many modes of operation as possible to achieve the best

debugging results and user experience.

Program Brief

Introduction

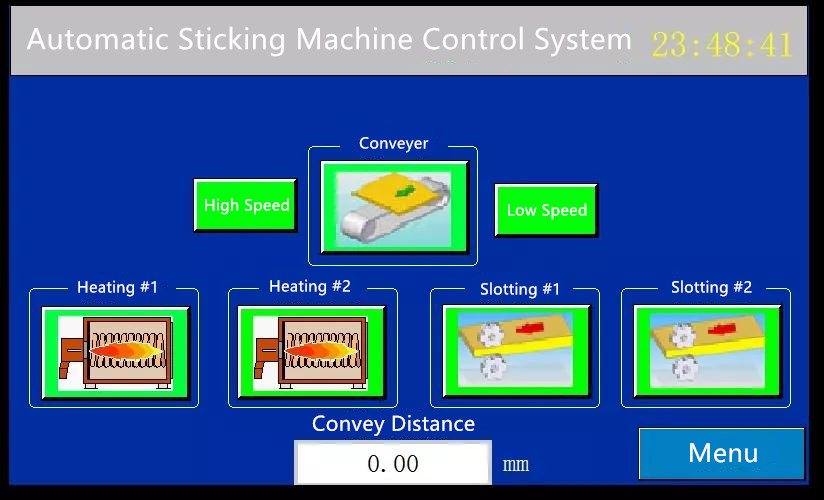

HMI program

Main Page

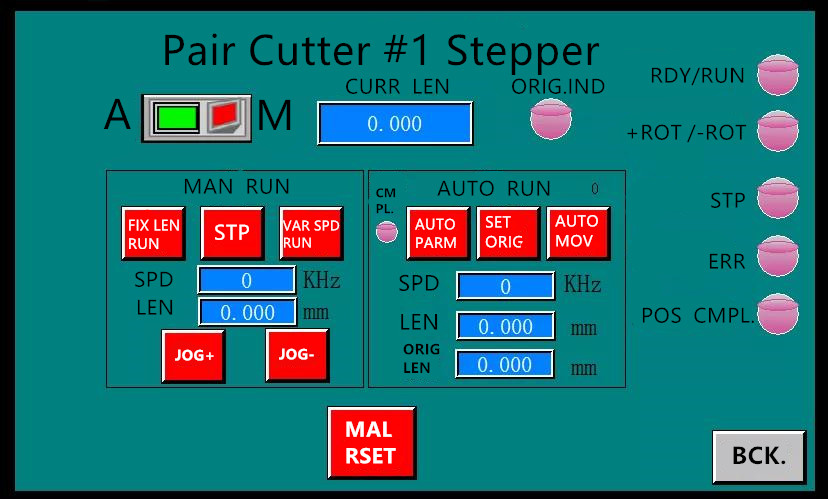

Motor Setting Page

Detailed Debugging Screen of One of the

Stepper Motors

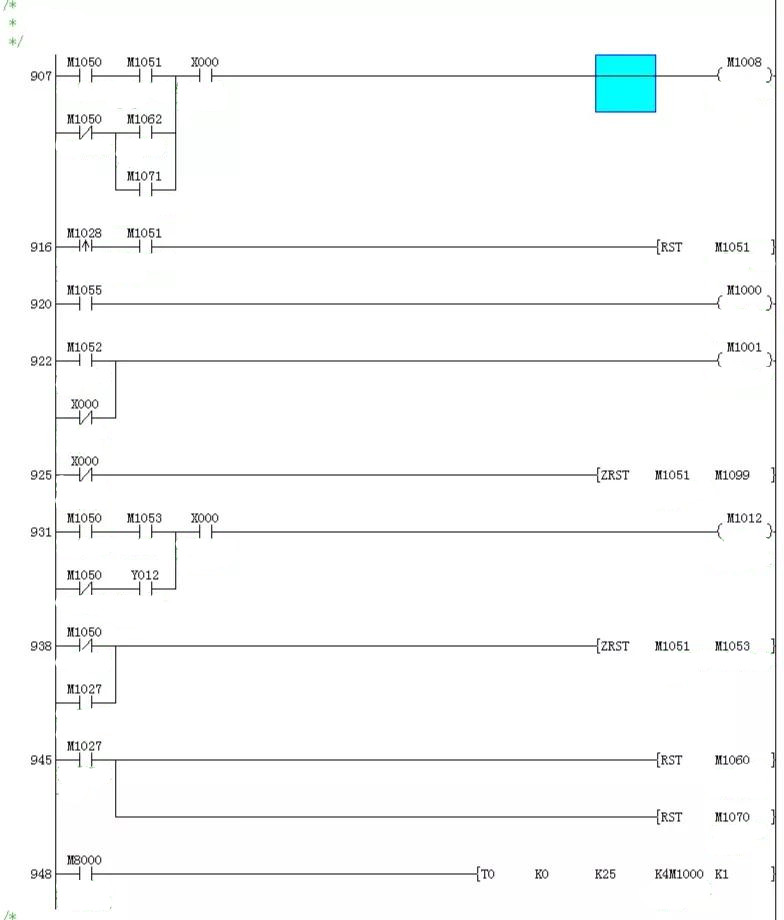

PLC Program

LX3V-4PG Manuel Setting

Project Summary

During the

debugging, there was a problem that the positioning of the stepping motor was

inaccurate. After many tests, the solution was found. That is, it is necessary

to connect a 2K resistor in series between the pulse and direction of the

stepping motor. This has something to do with the brand of the driver of

different stepping motors. It is recommended that the customer do the serial

processing regardless of the brand to ensure the accurate operation of the

equipment.

This debugging summarizes the following

points:

1.Select the plan according to the needs, not only considering the

cost, but also the compatibility of the general program.

2.For the LX3V-4PG

expansion module, it is necessary to pre-plan the address. The control

requirements of the six stepper motors are the same, but the addresses are

different. If you can pre-plan the addresses nicely, you can get twice the

result with half the effort.

3.For problems that arise during debugging, be

sure to check them from start to end, eliminate the factors of the problems one

by one, and finally fix the problems.