I.Brief

A automatic sterilizer widely is be used in medical, pharmaceutical and other industries.Some special occasions require higher quality of the air in the space,So people must carry out disinfection and sterilization of the working environment, to ensure the normal medical and scientific research.Usually people use automatic sterilizer to disinfect environment. Sterilization device has the advantages of simple operation, good sterilization effect.

1.Liquid level control: the disinfectant is stored

in the liquid storage tank. When the equipment is working properly, it must

ensure sufficient disinfectant and install liquid level detection

device

2.Air source control: to ensure adequate air supply and discharge the

vaporization of disinfection liquid into the air.

3.Metering pump: add

disinfectant to the evaporator

4.Evaporator: the main requirement is that the

evaporator temperature is constant,to ensure the normal vaporization of the

disinfectant

II.Scheme

Type

selection:LEVI-700E,LX3V-1616MT4H-A,LX3V-4PT,LX3V-4AD。

1.Levi-700E is used to

realize the operation of equipment,data adjustment and

monitoring.

2.LX3V-1616MT4H-A+LX3V-4PT+LX3V-4AD can realize external input

signal to control 4 step metering pump,temperature andand humidity acquisition,

liquid level measurement

3.The step metering pump mainly controls the amount

of liquid add to the evaporator every time

4.The evaporator mainly vaporizes

the sterilized liquid

5.The air pump mainly discharges the vaporized

disinfection gas into the air, so as to achieve the function of space

disinfection

Advantages: LEVI-700E HMI is intuitive response and easy to

operate.

LX3V-1616MT4H-A,can control four step motor at the same time, 4 way

high speed pulse, high output frequency, high control

precision

LX3V-4PT,LX3V-4AD can collect 4 temperature, read 4*analog and high

resolution

III.Program brief introduction (partial

screen)

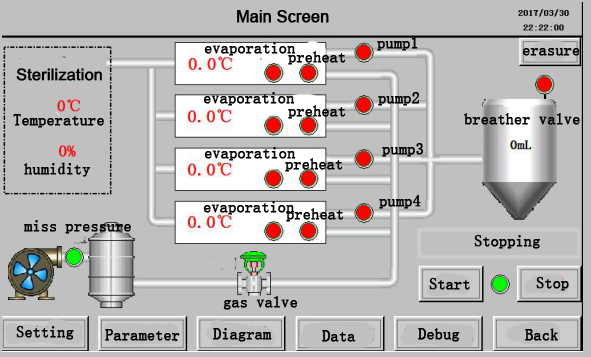

1.Main screen:This screen is main screen.It mainly shows

the working flow and the current working state of the 4 way

sterilize

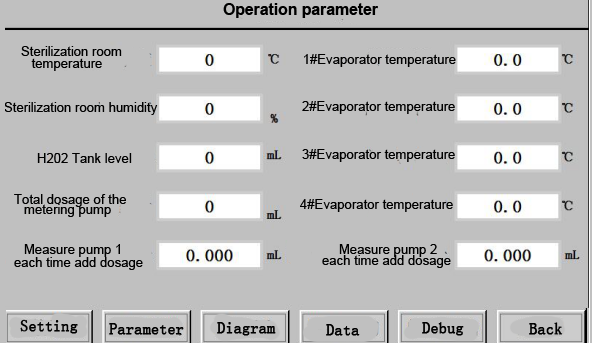

2.Parameter screen:This screen mainly set the parameters of the

device.

3.running parameter screen:This screen is mainly to monitor the operation

parameters of the equipment

4.Single machine debug screen:This screen is mainly for the device can be

single step, mainly for debugging equipment

5.Data record:This screen records the parameters of equipment running and

adjust the parameters of the query time for each period of time to view, also

available USB derived.

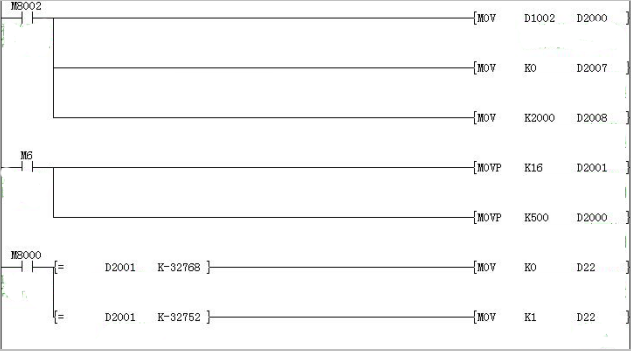

PLC part

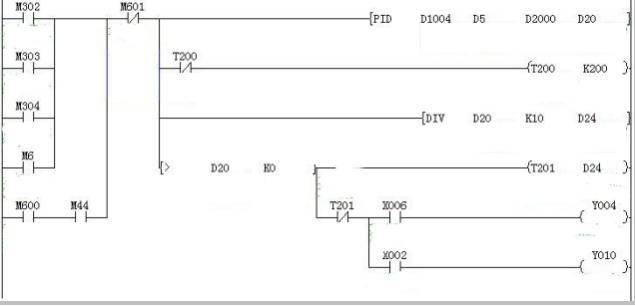

PID control

IV.sum-up of project

1.high speed pulse

output

2. PID temperature control

3.after analog output,to

calculate the conversion of the range