Ⅰ. Introduction

With the continuous impact of the COVID19, the cumulative number of new coronaviruses diagnosed in the world has exceeded 4 million cases, and the demand for masks has greatly increased. The main raw material for masks is melt-blown cloth, and the corresponding demand is also increasing. In order to expand the melt-blown cloth production capacity, the demand for melt-blown cloth extruders has grown rapidly.

Ⅱ. Process Requirements

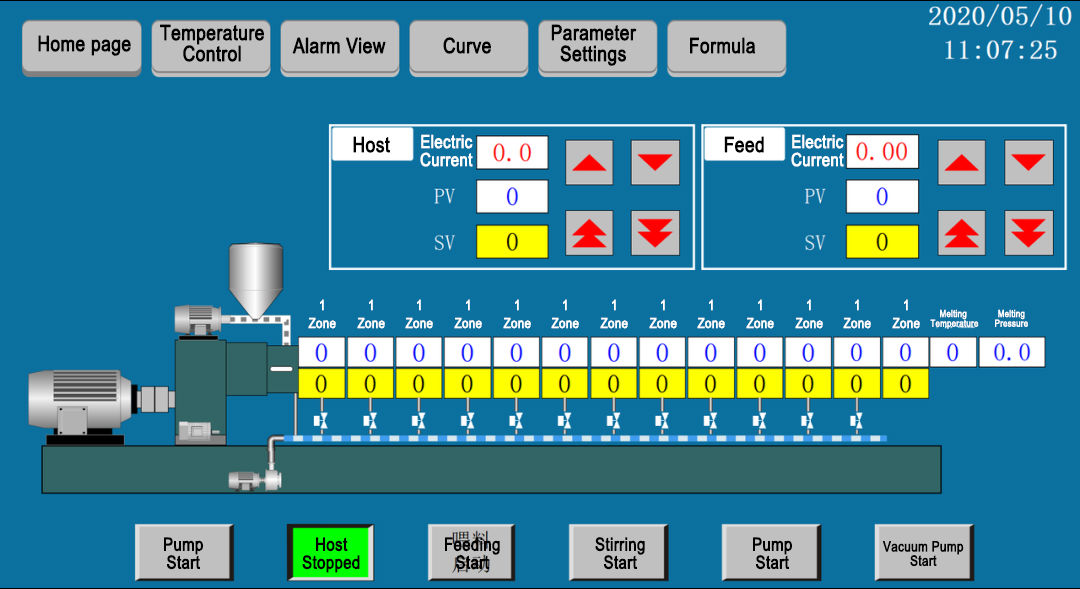

Melt-blown fabric extruders are mainly composed of temperature control system and molding system. The corresponding specific process requirements:

Part 1. Temperature control system: mainly controls 4 to 6 temperature zones for heating, heat preservation main frequency conversion motor and feeding motor, and controls the speed of feeding and discharging.

Part 2. Forming system: control of electret and winding.

Ⅲ. Solutions

The control system mainly uses the WECON human-machine interface PI8102H, and the PLC host uses CC3V-1412MT+LX3V-8ITC+LX3V-2AD-BD.

The brief plan is: PLC controls the temperature of temperature zone and each motor through PID algorithm, 8ITC module is responsible for collecting temperature.

Ⅳ. Solution Advantages

The system has strong stability and can realize remote real-time wireless monitoring.

Good compatibility, real-time modification of on-site process and PLC parameters.

It has a high degree of intelligence and can judge whether the system is running normally in real time.

High system integration.

Working parameters can be modified in real time during operation to simplify operation.

PID temperature control has high precision and small fluctuation.

Real-time collection of host current changes to protect the motor.

Ⅴ. Brief Introduction of the Procedure

HMI program:

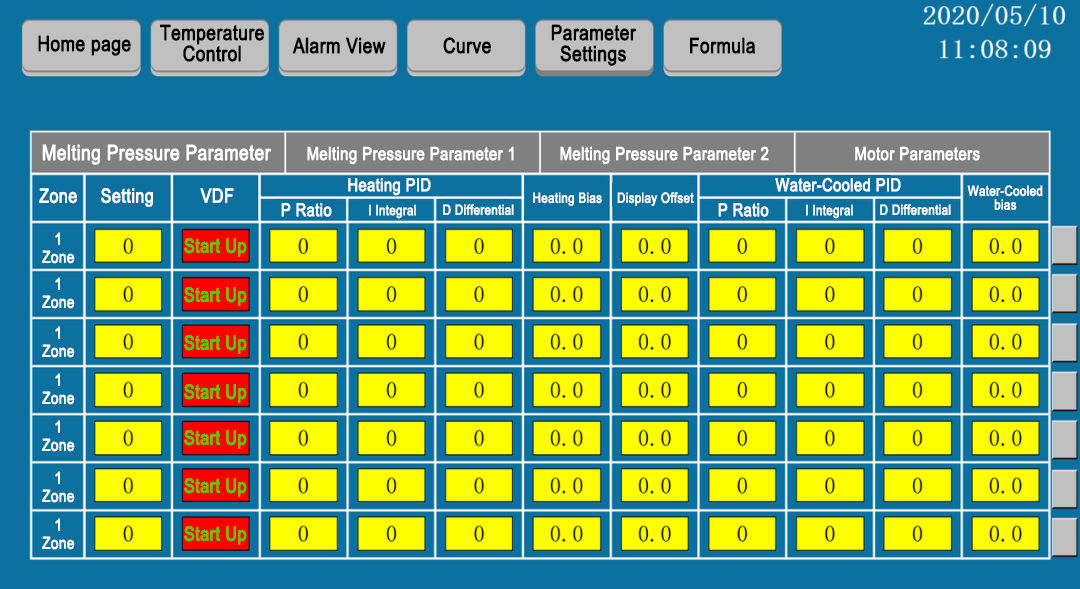

The parameter setting screen mainly provides customers with temperature control PID parameter setting, auto-tuning process, matching process of each motor current and speed, etc. In addition, we also provide customers with functions such as temperature display and record, product formula and so on.

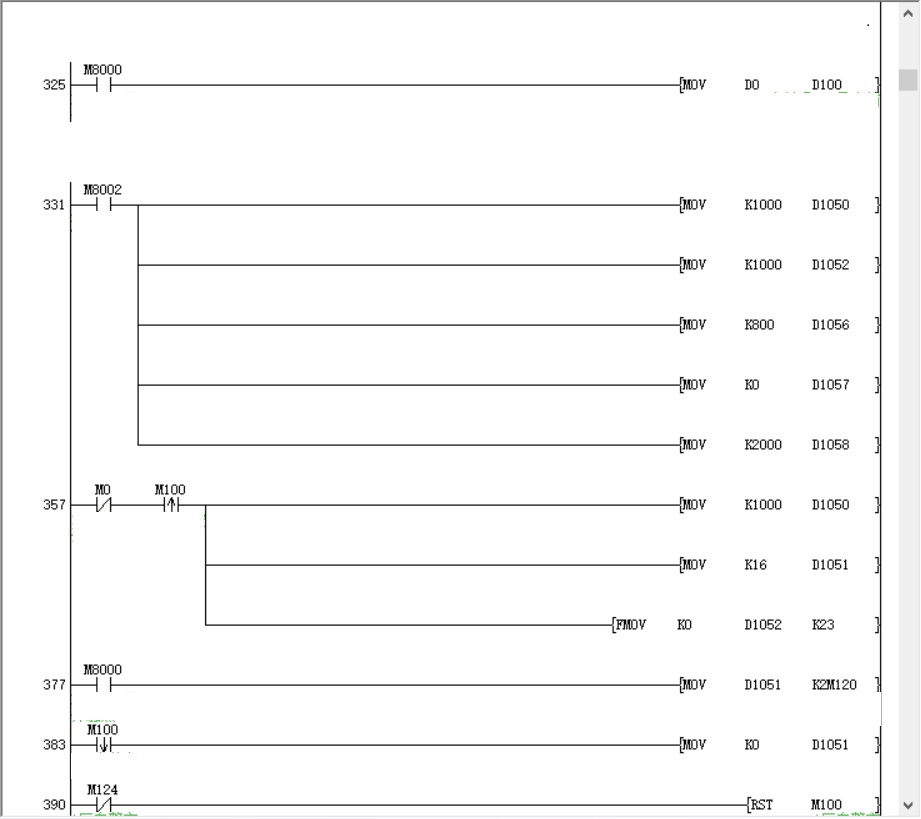

The following is part of the PLC program:

Ⅵ. Project Summary

The system mainly provides customers with a complete set of integrated control solutions for temperature control and mechanical control, which has the advantages of simple control and mature solutions. In addition, the system also has strong expansibility. When the temperature zone is extended to about 15 channels, it can be used as a production system for melt-blown cloth sliced polypropylene.

Ⅶ. Engineering Video and Machine Pictures