Background

After the outbreak of the epidemic, with the enterprises returning to work one after another, it is the top priority for each enterprise to prepare enough epidemic prevention materials and ensure the health of employees at all times, which also leads to the rise of the demand for respirator equipment.

As a high-tech company specializing in the research and development of products in the field of automation, WECON quickly gathers FAE with rich industry experience, studies the characteristics of mask machine and provides customers with the most powerful production scheme of full-automatic mask equipment in combination with market demand.

This paper mainly introduces the automatic control scheme of the third generation mask machine.

Overview of mask machine

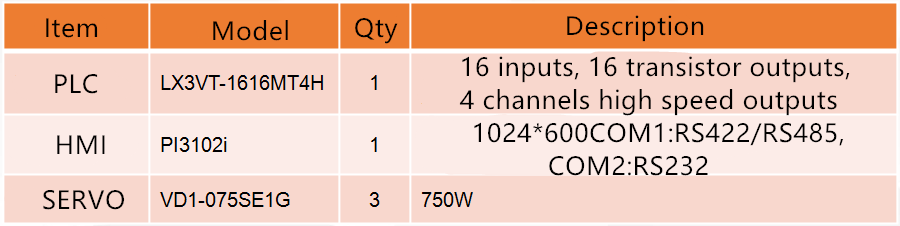

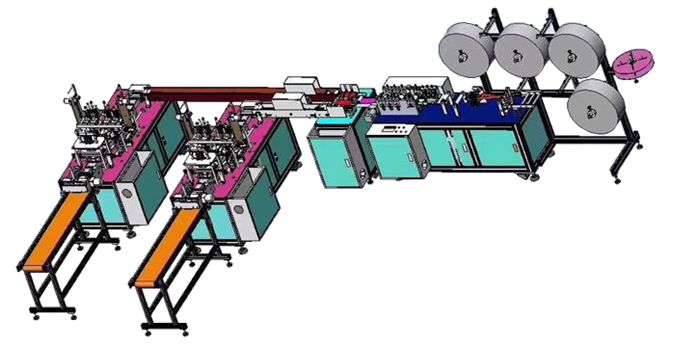

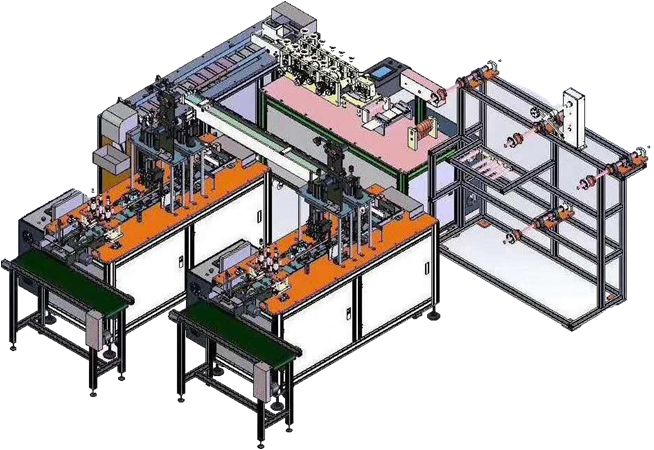

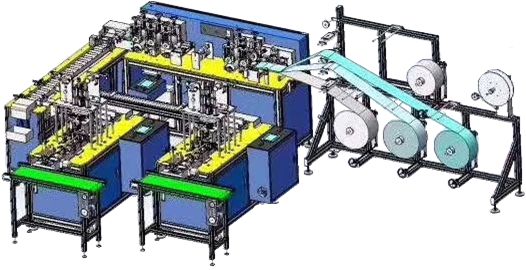

Mask machine equipment is divided into automatic plane mask machine and mask packaging machine. At present, there are three types of plane mask machine on the market: the first generation machine, the second generation machine and the third generation machine. (Picture as below)

First generation

Second generation

Third generation

Part I: main body of mask machine

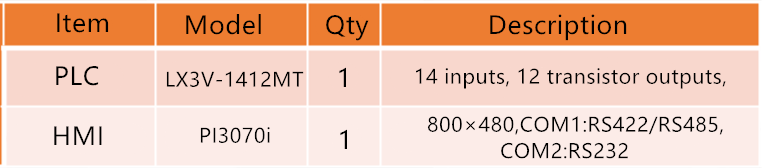

Press material slice, that is to say, fold, press and cut the non-woven fabric into one piece. The core of automatic control system is mainly composed of PLC, HMI, frequency converter, photoelectric switch, contactor and relay.

Part II:Distributing mechanism of mask

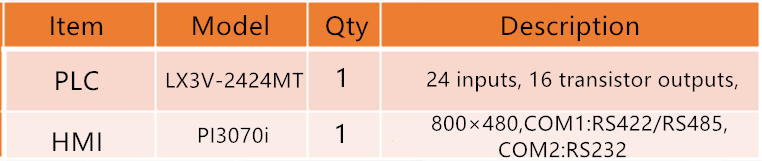

Pressing slice: feeding, that is, turning over the mask body after pressing slice and sending it to the part III for processing.

The core of automatic control system is mainly composed of PLC, HMI, step, photoelectric switch, contactor and relay.

Part III:Mask welding earphone

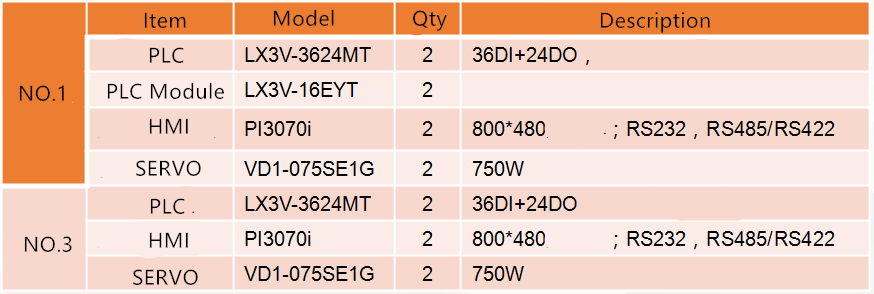

After pressing and cutting the mask body, the elastic belt is respectively welded on the left and right sides of the mask body and automatically wrapped.

The first generation system is mainly composed of one servo and multiple cylinders; the third generation system is mainly composed of one servo and three steps to replace some cylinder functions. The core of automatic control system is mainly composed of PLC, HMI, servo, step, photoelectric switch, contactor and relay.

Mask packing machine

The equipment is mainly used for the packaging of finished masks. According to different feeding methods, the system can be applied to the machine with chain and push plate as the feeding shaft and the automatic material handling machine with belt as the feeding shaft.

By collecting the blanking signal of the respirator packaging machine, and online production with the respirator machine, a respirator packaging production line can be formed, which can greatly reduce the number of workers who place the packaging manually (at present, most of the control systems on the market can only realize the single machine function).