The heat storage unit of the heat storage

tank utilizes the electricity price difference at different times. During the

nighttime period, the heat storage medium is heated to a set temperature and

stored, and stored in the form of hot water in the tank. During the daytime

period, the heating is released as needed to achieve full peak and flat

electricity consumption.

The PLC collects the analog temperature signals

such as the site temperature and pressure, and directly feeds back the operating

state of the field device. The advantage of this mode is that the signal output

and signal feedback have small interference and stable operation. The main part

of the control adopts the human-machine interface 7-inch LCD screen, which is

intuitive and easy to maintain.

1.Overview

1.1 Intelligent remote V-BOX control

Communicate with device controller over RS232/RS485/RS422/Ethernet to obtain device data

Connect to the cloud server through 4G/WIFI/Ethernet

Support standard communication protocols MODBUS, BACNET, 212, etc.

Customize protocols for users according to needs

Communication protocol for supporting common PLC controller in the market

Support SMS, email function

Support for OPC, private cloud and cloud SCADA

Support PLC remote download, remote debugging

Support APP monitoring

1.2 Features

1.3 Large screen monitor display

The data statistics of the electric boiler heat exchanger unit are displayed on the map, including the number of equipment in normal operation, the number of equipment that are shut down, the equipment failure rate, and various statistical analysis reports.

Click on the device to display various parameters, so that the user knows the running status of the device.

1.4 Alarm record display

Find all alarms on the map and click to view all information about the device

444

2. Features

(1) Support main PLC brand and a variety of Internet access methods;

(2) Data monitoring and device management functions are available in PC, mobile APP, web page;

(3) Support multi-user solutions, which can realize equipment management personnel, field service personnel, terminal customers and other people with different limits to access and monitor different equipment;

(4) The data is transmitted to the cloud data server remotely, and the data can also be stored locally, with the characteristics of remote query and resume transmission, to ensure the data integrity of the system.

(5) Remote program uploading and downloading of remote PLC program, online debugging program, saving a lot of manpower, financial resources, and greatly improving operation and maintenance efficiency.

2.1 Programmable Controllers

The electric heat storage adopts the programmable controller PLC, and collects the simulation data (voltage liquid level temperature, etc.) through the serial port RS422 data transmission, and then integrates and processes through the internal program to achieve unattended automatic control. Analog data such as pressure and temperature are displayed on the touch screen of the monitoring station.

2.2 System Structure

V-net IoT architecture has four layers: System control layer, data acquisition layer, Transport layer and application layer

(1)System control layer

The system control layer uses Wecon plc and modules, PLC collects pressure data, flowmeter, other real-time and accumulated data through RS485 or analog module. Motor and other driving overall system operation and feedback are under control by PLC ladder.

(2) Data acquisition layer

The data acquisition obtains all kinds of information of the equipment layer over Ethernet port or serial port in V-BOX. V-BOX obtains some data of the equipment for monitoring and data analysis, such as pressure, pool water level, system usage, etc.

(2)Transport layer

The transport layer consists of a variety of networks, including the Internet, radio and television networks, private networks, VPN, wireless mobile communications and cloud computing platforms, which are responsible for delivering and processing information obtained by the perceptual layer.

V-box is intelligent data acquisition tool specifically designed for IoT system applications, which can access the common plc in the market. The data go to cloud server through Ethernet, 4G network. Local data storage is enabled when Internet disconnected, then resume data transmission when Internet connected, which ensure the integrity of the data.

(3) Application layer

V-box connects with SCADA through OPC tool, all functions are running in the cloud, user can flexibly configure real-time data, trend charts, reports, alarms, mobile apps etc. Skilled programmer is not required. The data of each node(Gate state, pool water level, etc) is collected to realize the dynamic display of the information of the entire test point. Automatically send alarm message via email or WeChat.

3. Control System

The electrical control system of the electric heat storage device consists of the following parts:

(1) electrical control cabinet;

(2) PLC host control system;

(3) security protection system;

(4) the superior computer equipment operation screen monitoring system;

(5) electrical control system structure:

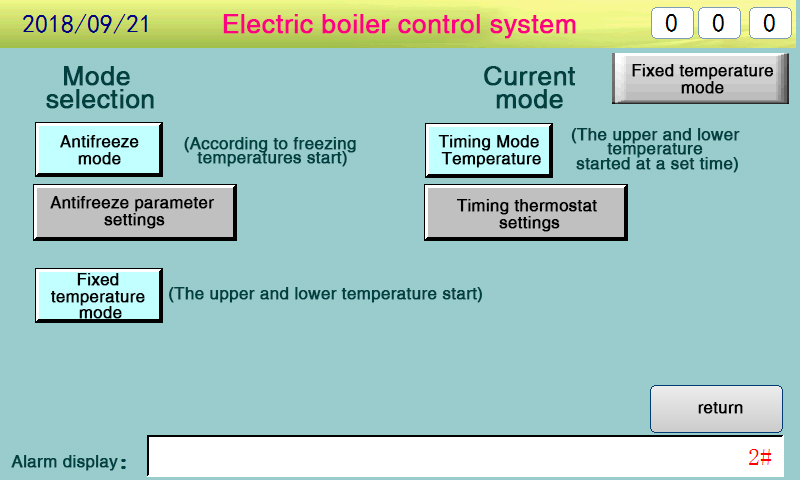

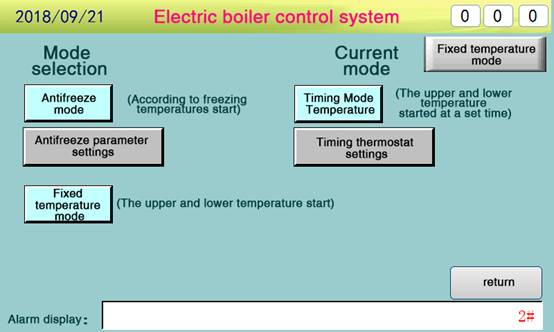

4. Multiple work control modes

4.1 Method 1: Antifreeze mode

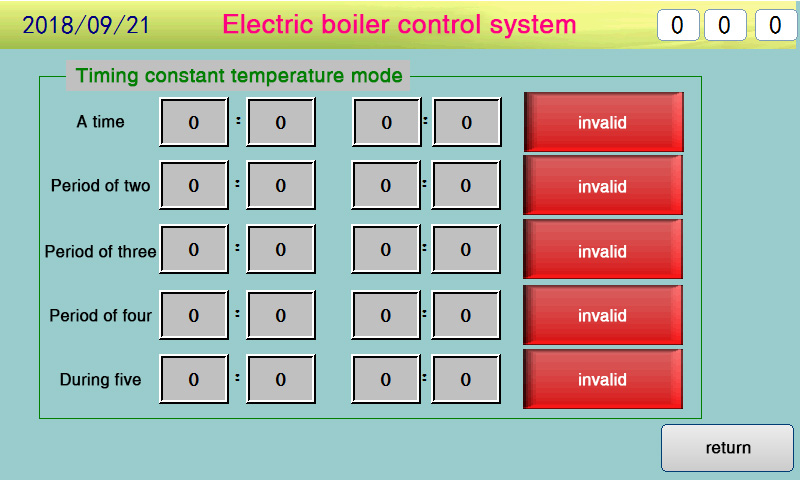

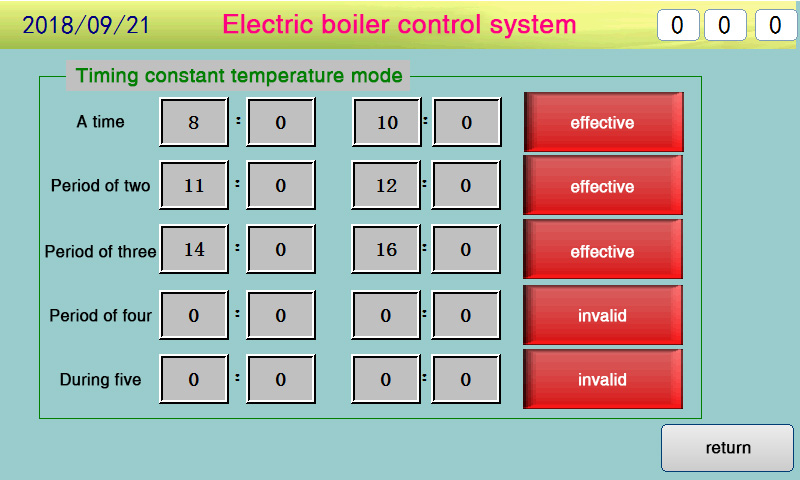

4.2 Method 2: Timing constant temperature mode

4.3 Method 3: Constant temperature mode

5.Controller and operation method

5.1 Operation monitoring interface

5.2 Control mode and temperature correction settings

Segmented working time for heat storage and heating functions

5.4 It displays the current status, pump and valve operating status, including execution time, etc., for automatic setting, fault alarm, etc.

5.5 Fault alarm display

The operation of the device is intuitive. The fault information is displayed directly on the display screen. The maintenance personnel judge the fault location of the equipment according to the fault information and perform maintenance.