1.Industrial Overview

The uncoiling machine is a machine that performs a series of processing operations such as uncoiling, leveling and shearing of metal plates.

2. Process flow and Control Requirements

This series of production line is used to roll metal or other materials of different specifications into flat plates of required length and width after uncoiling, leveling, setting size, and cutting. It is suitable for processing cold rolled plate, galvanized plate, color coated plate, stainless steel plate and other plates.

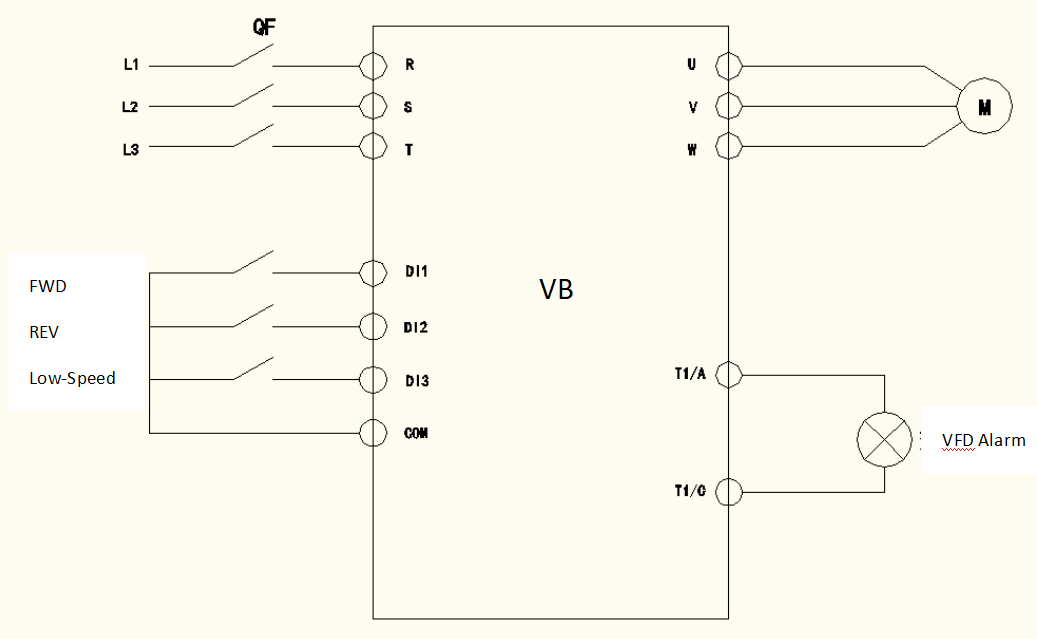

3.Electric Diagram

4.Parameter Settings

| Parameter | Description | Set Value | Remarks |

| F0.01 | Start/Stop Order Source | 1 | DI Terminal |

| F0.03 | Frequency Source | 6 | Multi-Stage Speed |

| F0.18 | Acceleration Time | 1.0 | 1S |

| F0.19 | Deceleration Time | 1.0 | 1S |

| F1.11 | DC Braking Beginning Frequency at Stop | 5.0 | |

| F1.13 | DC Braking Current at Stop | 80.00 | 80% Rated Current |

| F1.14 | DC Braking Period at Stop | 10.0 | 10S DC Braking |

| F4.00 | V/F Curve | 1 | Multi-point V/F Curve |

| F5.00 | DI1 Option | 01 | Forward running (FWD) |

| F5.01 | DI2 Option | 02 | Reverse running (REV) |

| F5.02 | DI3 Option | 12 | Multi-stage Speed Command 1 Terminal |

| FD.01 | Multi-stage Speed 1 | 20.0 | 10HZ |

| FD.51 | Multi-stage Speed Command 0 Source | 6 | Keypad Potentiometer |

5.Program Features

1)The system adopts VB high-performance VFD, which can start and stop the equipment quickly and stably. It has the characteristics of large starting torque and small impact on the power grid, especially for the reliable guarantee of long-term operation.

2)All-round protection function: VB has overload, overcurrent, overvoltage, phase loss protection, which greatly improves the safety of the system.

3)VB optimizes the braking curve, increases the system stability, and can better improve the equipment output.