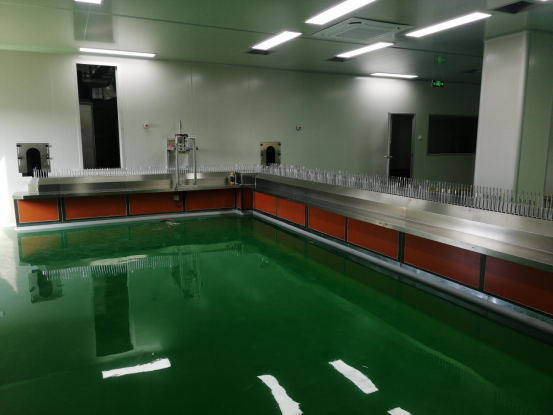

The spraying operation has high production efficiency and is suitable for manual operation and industrial automation production. It has a wide range of applications, mainly in the fields of hardware, plastics, furniture, military industry, ships, etc. It is the most commonly used painting method today. The spraying operation requires environmental requirements There are dust-free workshops with a dust reduction level of one million to one hundred. The spraying equipment includes spray guns, spray booths, paint supply rooms, curing ovens/drying furnaces, spraying workpiece conveying equipment, mist elimination and waste water, waste gas treatment equipment, etc.

Spraying is a coating method that is dispersed into uniform and fine droplets by means of pressure or centrifugal force through a spray gun or disc atomizer and applied to the surface of the object to be coated. It can be divided into air spraying, airless spraying, electrostatic spraying and various derivatives of the above-mentioned basic spraying forms, such as high-flow and low-pressure atomizing spraying, thermal spraying, automatic spraying, multi-group spraying, etc. Fix the product to be sprayed on the rotatable bracket, and then lock the bracket on the assembly line, through the movement of the assembly line and the continuous rotation of the rotatable bracket to achieve 100% uniform spray on the surface of the product.

| Parameter | Description | Value | Remark |

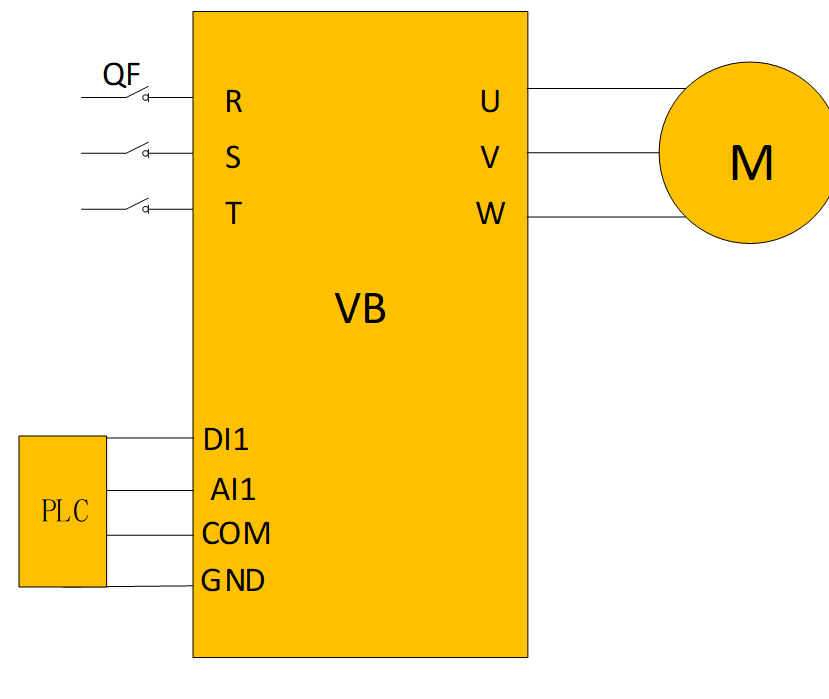

| F0.01 | Start/Stop Order Source | 1 | External Terminal |

| F0.03 | Frequency Source | 2 | AI1 Analog Input |

| F0.18 | Acceleration Time | 8 | 8s |

| F0.19 | Deceleration Time | 8 | 8s |

| F4.16 | AVR Function | 0 | Invalid |

| F5.15 | DI Filtering | 0.1 | DI Filtering Time |

Due to the large number of VFDs in a cabinet, the signal wires and the power cables cannot be completely separated, so it is necessary to pay attention to the interference between the VFDs.

VB series VFD performance advantages:

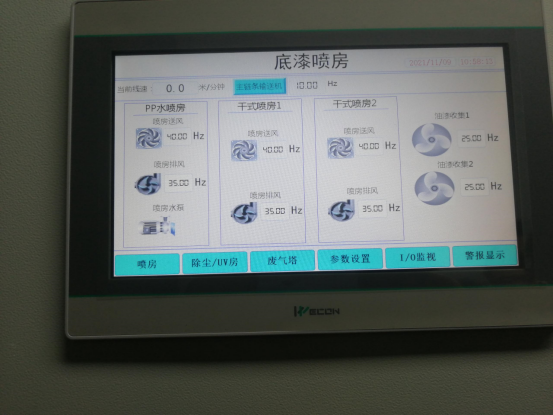

1. With digital input and analog input functions, an external host computer can be connected to realize different transmission speeds corresponding to different production processes, so as to meet the speed regulation requirements of the production system;

2. Control the movement of the assembly line and the continuous rotation of the rotatable bracket through the inverter, so as to achieve 100% uniform spray on the surface of the product;

3. The V/F control method is adopted to make the whole starting process more stable and without impact;

4. The perfect protection system can protect the whole system from overvoltage, overcurrent, overheating and short circuit to ground.