Sesame is an important high-quality oil crop and an export-earning agricultural product in China. In the technological process, it is necessary to soak the raw materials with water and wash to separate the skins and kernels of the sesame seeds.

Raw sesame → washing → soaking → peeling → separation of skin and kernel → dehydration → drying → selection → packaging → delivery

1. [Soaking process] The purpose of soaking is to make the sesame skin absorb water and expand, which is conducive to peeling from the kernel.

2. [Peeling process] A vertical drum peeling machine is used to make the sesame move relatively in the container, and use the gentle friction between the sesame and the sesame to peel off the cortex.

3. [Separation process of skin and kernel] This process is the most important part of the production of sesame kernels, which is related to the yield of finished products. Using the principle of separating sesame husks and kernels with different geometric dimensions, a sinking type automatic separation equipment and technology of sesame husks and kernels is adopted. The best soaking process is used to soften the sesame husk, and the brokenness of the sesame hull is increased during peeling without affecting the integrity of the sesame kernel. The volume difference of the sesame husk is smaller than that of the sesame kernel. The water flow takes away the sesame skin and the sesame kernels are retained, so as to achieve the purpose of separating the sesame skins and kernels, greatly reducing the labor intensity of workers, and the yield of finished products is also very high.

| Parameter | Description | Value | Remarks |

| F0.01 | Start/Stop Order Source | 1 | External Switch |

| F0.03 | Frequency Source | 2 | PLC to AI1 |

| F0.18 | Acceleration Time | 120 | 120S |

| F1.11 | DC Braking Starting Frequency at Stop | 0.5 | |

| F1.13 | DC Braking Current at Stop | 80.00 | 80% Motor Rated Current |

| F1.14 | DC Braking Time at Stop | 10.0 | 10S |

| FA.03 | Overvoltage Stall Gain | 000 | Braking Unit Equipped |

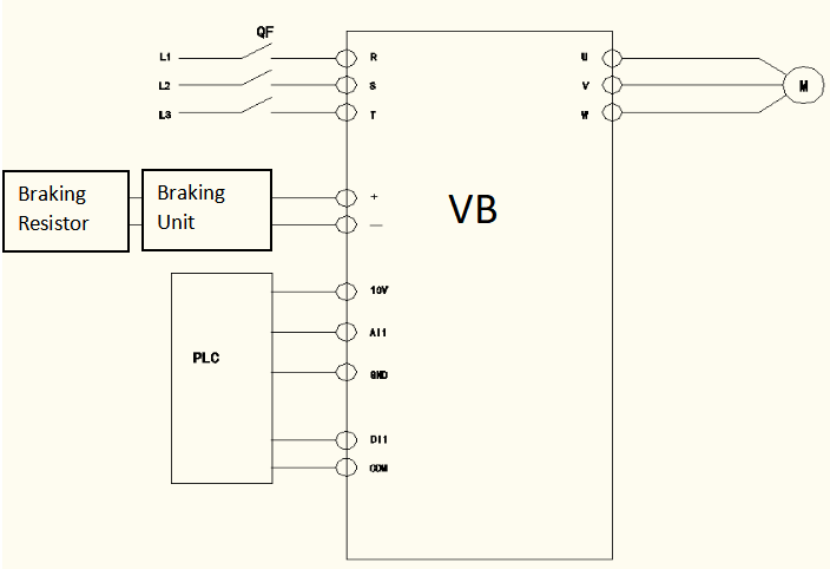

1)The system adopts VB high-performance VFD, which can start and stop the equipment quickly and stably. It has the characteristics of large starting torque and small impact on the power grid, especially for long-term operation.

2)All-round protection function: VB VFD itself has overload, overcurrent, overvoltage, lack of equal protection, which greatly improves the safety of the system.

3)VB optimizes the braking curve, increases system stability, and can better improve equipment output.