With the development and progress of society, "green, environmental protection and sustainable" has been continuously mentioned in industrial production in recent years. However, in the traditional rubber production process, there will be a lot of harmful gases, energy waste, low efficiency, and insufficient energy saving. It is also imminent to reduce emissions, and then transform from open mixer to internal mixer to frequency converter application. From the open mill to the internal mixer, the emission of harmful gases can be effectively reduced. From the internal mixer to the application of VB series VFDs, the entire system has improved production efficiency and effectively reduced energy waste, and has also greatly improved the automation of rubber production.

The working principle of the internal mixer is to add raw materials at a specific temperature (depending on the materials used, some need to be heated, and some need to be cooled), and through the rotation of the rotor, the materials are sheared by using different speeds and speed ratios. And pressure, so as to break the molecular chain of the material, to achieve the plasticizing temperature environment, to mix the raw materials, so as to achieve the purpose of mixing, so that various additives and masterbatch can be fully mixed, so that the components can be evenly distributed .

(1) During production, it is necessary to adjust the speed according to the rubber mixing speed of different materials;

(2) The soft start function is required to achieve smooth start without large inertial impact, etc.;

(3) Control parking function, smooth parking function.

(4) When adding too much material, it can automatically reduce the speed without reporting a fault。

| Parameter | Description | Set Value | Remarks |

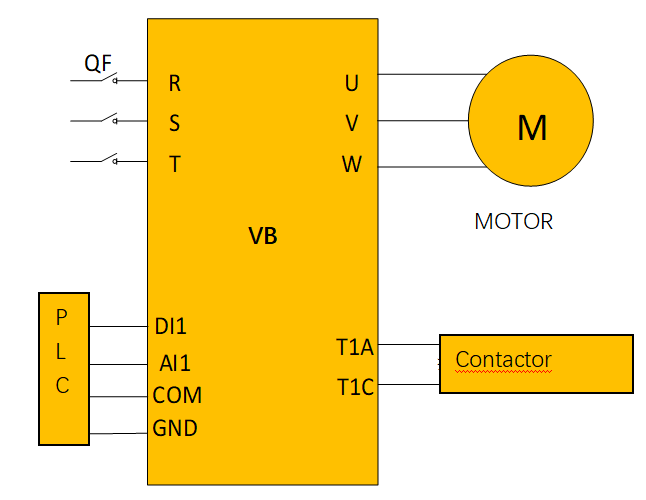

| F0.01 | Start/Stop Order Source | 1 | DI Terminal |

| F0.03 | Frequency Source | 2 | AI1 Analog Input(0-10V) |

| F0.18 | Acceleration Time | 80 | 80s |

| F0.19 | Deceleration Time | 80 | 80s |

| F4.11 | Oscillation Suppression Gain | 10 | |

| F4.16 | AVR Function | 0 | AVR Off |

| F6.02 | Relay 1 Option | 41 | User-defined Output |

| F6.28 | User-defined Value | 4 | Output Current |

| F6.29 | Comparison Option | 11 | Output when User defined value is equal or above F6.31 |

| F6.31 | Comparison Value | 4500 | 450A |

| FA.05 | Overcurrent Stall Suppression Gain | 50 |

(1) The VB VFD has excellent acceleration and deceleration performance. It starts completely steplessly and smoothly when starting, has no impact on the power grid, and fully protects the motor, equipment machinery and power grid impact.

(2) VB has automatic current limiting, automatic torque boost, and when the current is too high, it will automatically reduce the frequency to reduce faults.

(3) To meet the flexible production process, the speed of products corresponding to different production materials can be adjusted freely, which greatly improves the production efficiency and quality.

(4) VB VFD has a complete protection system, which can protect the entire system from overvoltage, overcurrent, overheat and short circuit to ground.