Chili peppers have been loved by many Chinese people since their introduction to China during the Ming Dynasty, especially in areas with humid and hot climates and cold temperatures. Chili peppers are hot and loose in nature, warm and cold in nature, and rich in vitamins, making them an indispensable vegetable and seasoning for every family. In modern times, food factories also use chili peppers to make various delicacies and seasonings.

Such a huge amount of usage, if not stored properly, will rot and cause waste. The common practice is to dry the chili peppers and store them. Drying hundreds or thousands of tons of chili peppers requires professional large-scale drying machinery, and automated drying machines equipped with VM1000B VFD highlight their huge advantages in this industry.

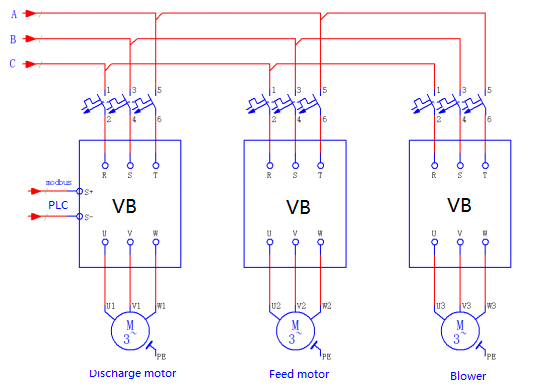

Pepper dryer is a batch and continuous production drying equipment, whose main principle is to evenly lay materials on a mesh belt, which is dragged back and forth by a transmission device in the dryer. Hot air flows through the materials, and water vapor is discharged from the dehumidification hole to achieve the purpose of drying. The main links are hot air conveying, material conveying, and material output. The motor drive of these links is completed by the VFD

1)The hot air required for drying is generated by heating the boiler and blown into the drying equipment through a fan, which is equipped with a frequency converter and can adjust the speed to adjust the air volume.

2)The motor of the material conveyor belt also needs a VFD to adjust the feeding speed and discharging speed, in order to adjust the dryness and wetness of the materials left in the dryer.

wiring diagram:

| Parameter | Description | Set Value | Remark |

| F0.01 | Start/Stop Order Source | F0.01=2 | RS 485 Communication |

| F0.03 | Frequency Source | F0.03=9 | RS 485 Communication |

| FC.00 | VFD Address | FC.01=1 | |

| FC.01 | Baud Rate | FC.01=3 | Baud Rate 9600 |

| FC.02 | Parity Option | FC.02=3 | 8-bit,none parity,1-bit ending |

Due to the use of a VFD to drive the motor of the chili dryer, the following benefits have been achieved for customers

1. Intelligent feeding and discharging, achieving less manual operation and saving labor;

2. The feeding speed can be adjusted according to the actual heating situation to achieve uniform heating and high drying rate of chili peppers;

3. Protect the motor with various protections such as overcurrent, overvoltage, overload, undervoltage, etc., to extend its service life;

4. Variable frequency speed regulation replaces air dampers to regulate air volume and save electricity.