Central air conditioning system is an indispensable and important component in modern buildings. With the improvement of people's living standards and the acceleration of urbanization, the application of central air conditioning systems is becoming more and more widespread, and the market size is increasing year by year. In the past decade, the application scope of central air conditioning systems has continued to expand, not only in traditional commercial and industrial fields, but also in residential, medical, transportation and other fields. Energy saving, environmental protection, comfort and safety have become the main technical features of central air conditioning systems.

With the continuous advancement of technology, the energy efficiency ratio and performance coefficient of central air conditioning systems continue to improve, which has also made a significant contribution to energy conservation and emission reduction.

However, there are currently some pain points in central air conditioning system technology:

1) Energy saving: How to reduce energy consumption and improve energy utilization efficiency is the top priority of the current central air conditioning system.

2) Intelligence: How to use intelligent technology to realize automatic control and remote monitoring of the central air-conditioning system to maximize user satisfaction?

3) Diversification: How to make different types of central air conditioners cope with different usage scenarios to meet the needs of users?

4) Safety: How to strengthen the safety performance of central air conditioning and improve the safety, reliability and stability of the system?

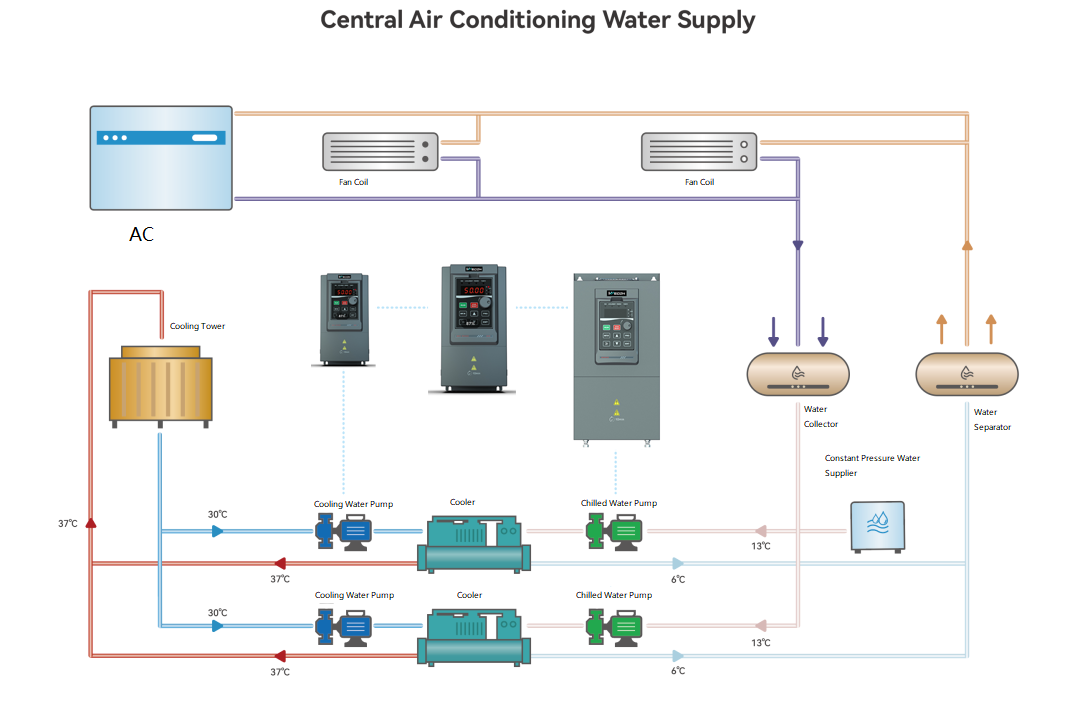

The refrigeration principle of the central air-conditioning system is liquid vapor refrigeration, which achieves refrigeration by removing part of the vapor. The high-temperature gas increases the temperature of the water, condenses into liquid, and then evaporates into low-temperature gas, continuously circulating to achieve refrigeration. The heating principle is that the compressor inhales low-pressure gas and compresses it into high-temperature gas, increases the water temperature through the heat exchanger, and then condenses it into a liquid. The liquid enters the evaporator and evaporates into low-temperature gas, which is continuously circulated to deliver hot water to the room that needs heating to achieve heating.

System schematic diagram

VB VFD can achieve various purposes such as energy saving, improving system stability, safety and intelligence by automatically adjusting refrigeration pumps, cooling pumps and other equipment in central air-conditioning systems.

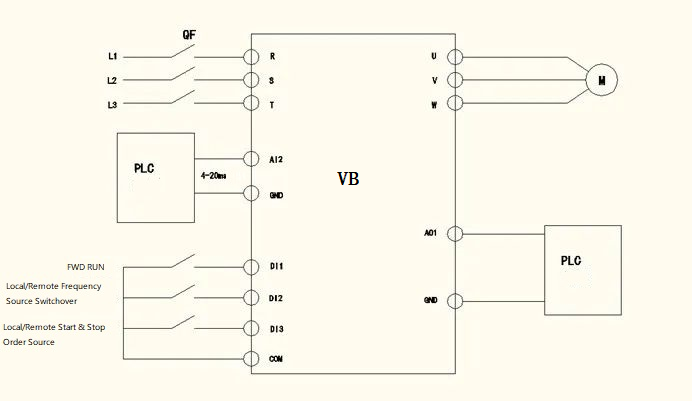

Electrical control diagram

Parameter Settings

| Parameter | Description | Set Value | Remarks |

| F0.01 | Start & Stop Order Source | 1 | DI Terminal |

| F0.03 | Main Frequency Source X | 3 | AI2 |

| F0.04 | Auxiliary Frequency Source Y | 0 | Keypad |

| F0.07 | Frequency Calculation Option | 02 | Switchover between X & Y |

| F0.18 | Acceleration Time | 30.0 | 30S |

| F0.19 | Deceleration Time | 30.0 | 30S |

| F5.00 | DI1 Option | 01 | FWD Run |

| F5.01 | DI2 Option | 18 | Switch Frequency Source |

| F5.02 | DI3 Option | 20 | Switch Start & Stop Order Source |

| F5.23 | AI2 Maximum Input | 2.0 | AI2-4ma |

| F6.15 | AO1 Coefficient | 20.0 | AO1 Output 4~20mA |

| F6.18 | AO1 Gain | 0.8 |

In the case application, VB VFD demonstrated multiple effects.

First, it has significant economic and energy-saving advantages. Through microcomputer control, the system can automatically adjust the temperature of the end air duct to achieve automated operation. The coils can be turned off even when no one is using them, further saving energy.

Secondly, the application of VB high-performance VFD makes the equipment start and stop more quickly and stably, and has the advantages of large starting torque and small impact on the power grid. This provides more efficient and reliable guarantee for long-term operation.

In addition, it has overload, overcurrent, overvoltage, phase loss and other protection functions, which can greatly improve the safety of the system. This enables the system to protect itself promptly and effectively in the face of various possible problems, further ensuring the stability and reliability of the system.

Finally, VB’s optimized programmable DI terminal allows the VFD to easily cope with the requirements of various occasions. It also provides greater flexibility for practical applications. Users can customize settings and operations according to actual needs to meet various application scenarios.